CYBERLYNK didn’t start as a product idea. It started from a recurring frustration.

Across years of delivering automation, and IT systems in regulated manufacturing environments, we kept encountering the same problem — integration issues arising after equipment has been delivered to site.

Not because teams weren’t capable. But because the industry had accepted that meaningful integration could only happen after systems are delivered to the customer site.

Why was meaningful system integration only possible once everything was already on site?

Project after project, the same pattern appeared. FATs tested individual machines. SATs attempted to test entire systems. And only at that late stage did system integration issues emerge.

The problem wasn’t a lack of engineering effort or expertise. It was that the tools available, made early integration impractical. Integration wasn’t failing — it was simply happening too late.

What if we could integrate these systems earlier — during the vendor FAT?

CYBERLYNK was created to solve this problem.

Instead of accepting late-stage discovery as inevitable, we developed a solution to enable machines and control systems, to be securely connected and remotely tested before they reach the customer site.

By making pre-SAT possible during FAT, teams gain visibility when change is still easier, schedules are still flexible, and decisions are still reversible.

The CYBERLYNK device is the result of that shift in thinking.

It was shaped by real commissioning constraints, regulated environments, and the practical realities of OEMs, system integrators, and end customers working under pressure. Every design decision was driven by one goal: make early integration achievable without adding complexity or disrupting established workflows.

CYBERLYNK is designed to be introduced and adopted easily.

It does not require projects to be restructured, timelines to be extended, or existing tools to be replaced. Instead, it integrates into established workflows, providing teams with a new capability without adding friction.

By enabling earlier network and system integration, CYBERLYNK creates the opportunity to identify and resolve issues sooner — when schedules are still flexible and corrective action is straightforward.

The innovation lies not in changing how projects are run, but in expanding what teams can confidently test earlier in the lifecycle.

Our work is guided by a simple principle: manufacturing projects run best when risks are addressed early, not deferred to the final stages.

By shifting integration earlier, CYBERLYNK helps teams move from reactive problem-solving to controlled delivery. The result is smoother commissioning, more predictable timelines, and faster time to production.

CYBERLYNK was shaped in pharmaceutical manufacturing, where complexity, regulation, and integration risk are highest. That environment set the benchmark.

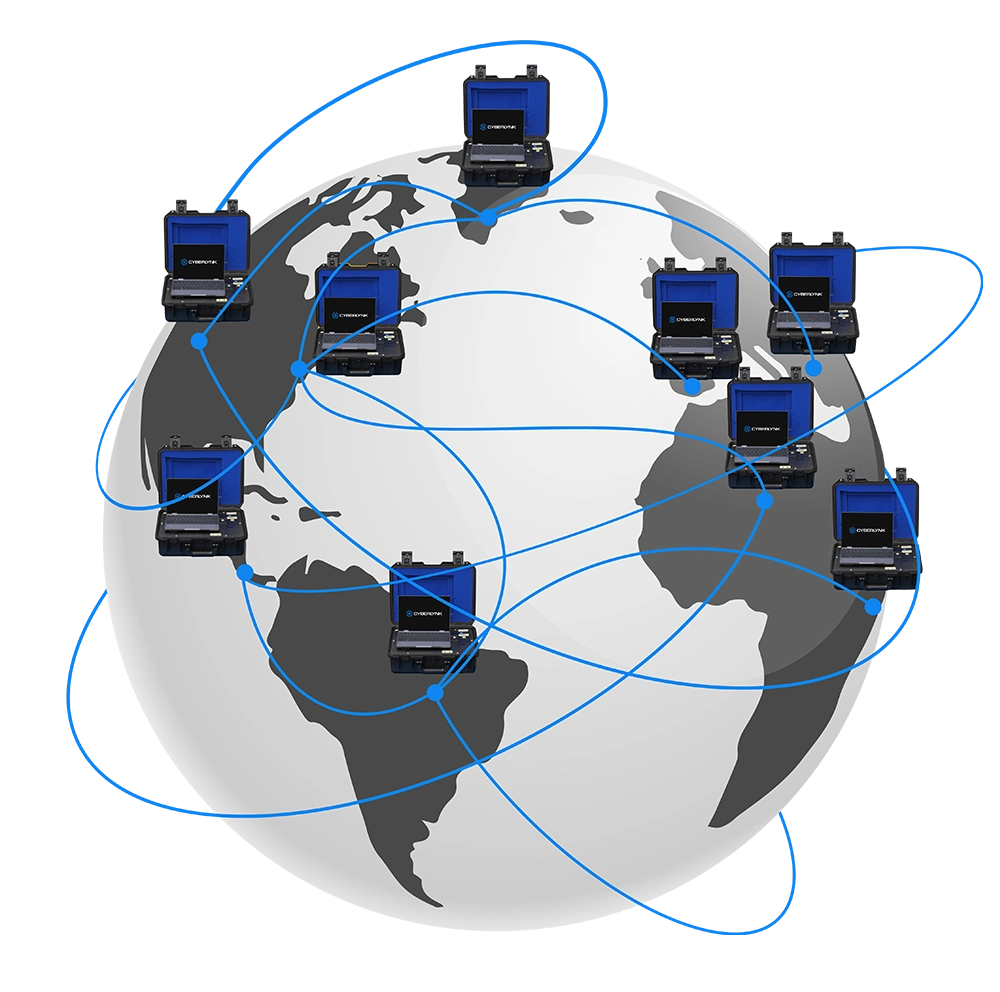

Looking ahead, our focus is global.

As manufacturing systems become more connected and software-driven, the challenge CYBERLYNK addresses is no longer industry-specific. From pharmaceutical to food and beverage, semiconductor, electronics, automotive, and cosmetics, the need to identify system integration issues earlier is the same.

Our ambition is simple: to make early, and secure system integration a standard capability across global manufacturing projects.

Have a project in mind? Get in touch to discuss further.